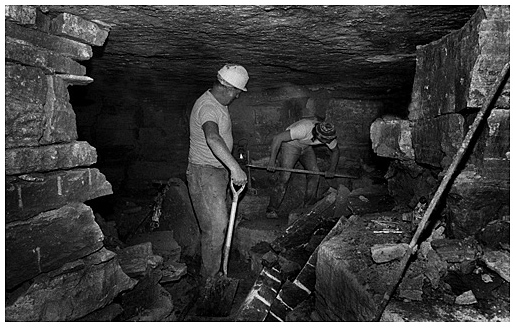

A scene from a masonry workshop in one of Purbeck’s stone quarries looking like the pages of a large book are being cut from Purbeck Marble - a Viviparus Gastropod dense limestone, the youngest formations of the Jurassic Period, deposited around 150-135 million years ago when Dorset was subequatorial and Portland was laid down in shallow warm sea - regressing to leave a freshwater lagoon in which the Purbeck Beds were formed - when life was compressed, solidified and transformed into Purbeck stone.

Little more than two or three feet thick the 'marble' veins are the topmost of the Upper Purbeck beds, varying in colour from blue, green to grey - when polished looks like marble +. The three veins can be traced along the 10 mile length of Purbeck, from Peveril Point in the east to Worbarrow Tout in the west.

‘Marble' first exploited during the Roman occupation probably at Wilkswood, north of Langton Matravers. The earliest shallow pits worked over as deeper quarrying took place. West at Quarr Farm and Downshay Burr limestone the bed immediately below the marble was quarried by the Normans for the building of Corfe Castle's keep in the early 12th century. The castle's first stone was laid over a thousand years ago when it was built for William the Conqueror's son King Henry 1. Throughout the 12th, 13th and 14th centuries the marble industry was centred in Corfe when it was extensively quarried for the interiors of our cathedrals and churches located as far north as Lincoln and Durham. Piers, shafts, monumental effigies and shrines turned and carved by hand. 3,000 marble pillars for Salisbury Cathedral came from Dunshay (a gift!) as did the marble for Temple Church in London regarded as the finest medieval example. For Temple's first refurbishment in 1840 marble was quarried west at Woodyhyde by quarrymen working underground in the tightest of spaces hampered by the water table and Wealden clay. Further west marble was quarried where it out crops at West Lynch below Kingston and beyond at Blashenwell.

Today, in the 1990's Purbeck Marble, extracted at Quarr farm by WJ Haysom and Son is processed along with Purbeck and Purbeck-Portland freestone in their masonry workshops at St Aldhelm's Quarry and Lander's Quarry + at Gallows Gore on Kingston Road.

Purbeck Beds (Freshwater deposit) Slabs were used as early as the Bronze age. Records show a lean period in the 15th and 16th centuries with activity picking-up after the Great Fire of London (1666) trade then fairly steady until the downturn of the Great Depression in the 1920's.

By the eighteenth century the industry was sinking mines, referred to by the quarrymen as 'quarrs', in order to get at the deeper Middle Purbeck beds or the 'Upper Building Stone'. Towards the end of the century Swanage largely exhausted and seeking a new identity pushed the industry west along the limestone ridge towards Langton (the further west the deeper the stone).

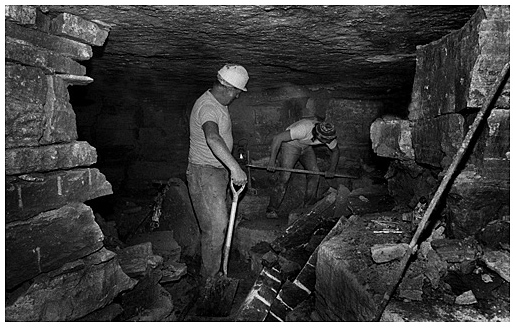

Working underground in narrow candlelit lanes, the stone varying in colour from pale blue-greys to rich warm beiges and browns was extracted for roof tiles and flat paving-stones (Downsvein commercially the most important 1650-1900). Selected slabs of Thornback were used for headstones and ledgers. The workable seams each named by the quarrymen.+ Lannen vein, Rag, Freestone, Downs vein, Cinder, Cap and Feather and New-vein. In all there are around twenty beds with names like Roach, Royal Rag, Grub, Thornback, Wetson and Brassey Bed. Rarely more than twelve men to a quarry usually just two or three worked in the smaller quarrs. The large blocks of stone were prised from the work-face by removing the thin under-picking (dirt layer) with a paddle. The block was then hauled by cart along a narrow corridor or 'lane' it's ceiling formed from the Ceiling or Grub bed supported by pit props or 'legs'.+ A capstan with rope (chain from 1800) it's wooden 'spack' harnessed to a donkey or horse then pulled the cart up the sloping shaft to daylight. The shaft had a stone-paved 'slide' with rough steps down each side for the quarrymen. Undergrounds existed until the outbreak of the war in 1939. In 1963 the government officially closed them down for safety reasons with the exception of one.

Little more than two or three feet thick the 'marble' veins are the topmost of the Upper Purbeck beds, varying in colour from blue, green to grey - when polished looks like marble +. The three veins can be traced along the 10 mile length of Purbeck, from Peveril Point in the east to Worbarrow Tout in the west.

‘Marble' first exploited during the Roman occupation probably at Wilkswood, north of Langton Matravers. The earliest shallow pits worked over as deeper quarrying took place. West at Quarr Farm and Downshay Burr limestone the bed immediately below the marble was quarried by the Normans for the building of Corfe Castle's keep in the early 12th century. The castle's first stone was laid over a thousand years ago when it was built for William the Conqueror's son King Henry 1. Throughout the 12th, 13th and 14th centuries the marble industry was centred in Corfe when it was extensively quarried for the interiors of our cathedrals and churches located as far north as Lincoln and Durham. Piers, shafts, monumental effigies and shrines turned and carved by hand. 3,000 marble pillars for Salisbury Cathedral came from Dunshay (a gift!) as did the marble for Temple Church in London regarded as the finest medieval example. For Temple's first refurbishment in 1840 marble was quarried west at Woodyhyde by quarrymen working underground in the tightest of spaces hampered by the water table and Wealden clay. Further west marble was quarried where it out crops at West Lynch below Kingston and beyond at Blashenwell.

Today, in the 1990's Purbeck Marble, extracted at Quarr farm by WJ Haysom and Son is processed along with Purbeck and Purbeck-Portland freestone in their masonry workshops at St Aldhelm's Quarry and Lander's Quarry + at Gallows Gore on Kingston Road.

Purbeck Beds (Freshwater deposit) Slabs were used as early as the Bronze age. Records show a lean period in the 15th and 16th centuries with activity picking-up after the Great Fire of London (1666) trade then fairly steady until the downturn of the Great Depression in the 1920's.

By the eighteenth century the industry was sinking mines, referred to by the quarrymen as 'quarrs', in order to get at the deeper Middle Purbeck beds or the 'Upper Building Stone'. Towards the end of the century Swanage largely exhausted and seeking a new identity pushed the industry west along the limestone ridge towards Langton (the further west the deeper the stone).

Working underground in narrow candlelit lanes, the stone varying in colour from pale blue-greys to rich warm beiges and browns was extracted for roof tiles and flat paving-stones (Downsvein commercially the most important 1650-1900). Selected slabs of Thornback were used for headstones and ledgers. The workable seams each named by the quarrymen.+ Lannen vein, Rag, Freestone, Downs vein, Cinder, Cap and Feather and New-vein. In all there are around twenty beds with names like Roach, Royal Rag, Grub, Thornback, Wetson and Brassey Bed. Rarely more than twelve men to a quarry usually just two or three worked in the smaller quarrs. The large blocks of stone were prised from the work-face by removing the thin under-picking (dirt layer) with a paddle. The block was then hauled by cart along a narrow corridor or 'lane' it's ceiling formed from the Ceiling or Grub bed supported by pit props or 'legs'.+ A capstan with rope (chain from 1800) it's wooden 'spack' harnessed to a donkey or horse then pulled the cart up the sloping shaft to daylight. The shaft had a stone-paved 'slide' with rough steps down each side for the quarrymen. Undergrounds existed until the outbreak of the war in 1939. In 1963 the government officially closed them down for safety reasons with the exception of one.

Harold Bonfield reopened his father's underground quarr at Verney on Priests' Way using a mobile crane to overcome its vertical access along with a compressor. Working the freestone vein around 50 feet deep until 1982 when operations ceased.+

Purbeck-Portland Beds (Marine deposit) 'cliff-stone' quarried from around 1670. From Swanage at Tilly Whim until 1810, Dancing Ledge until 1930, Blacker's Hole, Crab Hole, Cliff Fields, and Hedbury + Further west steam derricks and machinery were introduced in the 1920's at Seacombe which operated until 1931 and Winspit, the longest running of the cliff-side quarries, from the 1670's - West Winspit until 1953. Blocks of stone and finished products - sinks, troughs, gateposts, rollers and staddles were lowered over the edge of the cliff by derrick or whims, made of timber often from shipwrecks, into flat-bottomed craft and rowed out to a waiting barge or ketch giving way to steam tugs. 70 tonne loads were transported along the coast to Swanage and Poole - Between 1750-52 fifty ships were hired to transport 15,000 tons of stone from Purbeck for the building of Ramsgate Harbour - Purbeck's largest job totalling 94,000 tons: Inland open-cast quarrying returned, machinery was introduced and by the 1940's lorries had replaced horse & donkey.

Purbeck-Portland Beds (Marine deposit) 'cliff-stone' quarried from around 1670. From Swanage at Tilly Whim until 1810, Dancing Ledge until 1930, Blacker's Hole, Crab Hole, Cliff Fields, and Hedbury + Further west steam derricks and machinery were introduced in the 1920's at Seacombe which operated until 1931 and Winspit, the longest running of the cliff-side quarries, from the 1670's - West Winspit until 1953. Blocks of stone and finished products - sinks, troughs, gateposts, rollers and staddles were lowered over the edge of the cliff by derrick or whims, made of timber often from shipwrecks, into flat-bottomed craft and rowed out to a waiting barge or ketch giving way to steam tugs. 70 tonne loads were transported along the coast to Swanage and Poole - Between 1750-52 fifty ships were hired to transport 15,000 tons of stone from Purbeck for the building of Ramsgate Harbour - Purbeck's largest job totalling 94,000 tons: Inland open-cast quarrying returned, machinery was introduced and by the 1940's lorries had replaced horse & donkey.

At the height of manpower, in the mid 19th century, Swanage Parish had almost one hundred quarries, Langton and Worth the same again. Family run quarrs working their way through the stone above Swanage towards Langton and around Acton, Worth and Kingston. 'The arrival of the railway put an end to sea traffic' and as Trev Haysom puts it 'Utilitarian concrete has re-placed stone'.

Today just six operators extract Purbeck stone from ten quarries on National Trust land. With comparative ease diggers prise the creamish blocks of stone from their beds loading them onto articulated trucks for the workshops. + Primary and secondary sawn the stone is transformed and polished by monumental masons and their apprentices using traditional skills + and state-of-the-art machinery. Their workshops overlooking fields and traces of earlier quarrying activity. Gentle mounds, hollows and the overgrown remains of stone worksheds, situated at the entrances of disused underground quarrs can be seen from the footpaths that lead to the cliffs and galleries.

Published sources - Extracting Purbeck Marble - Trev Haysom 1998. Langton Stone Quarries - Reg Saville 1986. Peter Stanier - The Quarried Face, Evidence of Dorset's cliffstone quarries 1996.

Today just six operators extract Purbeck stone from ten quarries on National Trust land. With comparative ease diggers prise the creamish blocks of stone from their beds loading them onto articulated trucks for the workshops. + Primary and secondary sawn the stone is transformed and polished by monumental masons and their apprentices using traditional skills + and state-of-the-art machinery. Their workshops overlooking fields and traces of earlier quarrying activity. Gentle mounds, hollows and the overgrown remains of stone worksheds, situated at the entrances of disused underground quarrs can be seen from the footpaths that lead to the cliffs and galleries.

Published sources - Extracting Purbeck Marble - Trev Haysom 1998. Langton Stone Quarries - Reg Saville 1986. Peter Stanier - The Quarried Face, Evidence of Dorset's cliffstone quarries 1996.

Copyright © 2022 Jed Corbett